The Future of Construction: How Technology is Revolutionising the Building Industry

Explore how technology is revolutionising the construction industry with innovations like advanced robotics, AI-powered design, 3D printing, drones, and smart building technologies, reshaping modern construction practices.

Technology plays a vital role in every sector of the economy, particularly the construction industry. Lowering costs here makes new projects more viable, transforming how cities look and function.

Furthermore, it isn’t a single innovation driving these changes. Multiple technologies are making their presence felt in the sector.

This article explores some of the most exciting developments and how they may affect the industry, exploring what individual firms are doing to bring innovations to the market. We also ask why and how technology is transforming practices and processes, showing how they may drive higher efficiency, productivity, and sustainability in construction firms.

Technology Innovations In The Construction Sector

Advances in robotics, software, and artificial intelligence are driving innovation in the construction sector across multiple fronts. Companies are seeing how these innovations might improve outcomes and help them deliver better results to stakeholders.

Robotics

Robotics is the most exciting of all the technology developments rocking the construction sector because of the impact it could have on safety and efficiency. Using machines to create buildings instead of people could lower costs substantially, increase wages, and render worksites safe.

Ten years ago, robotic technology on building sites was science fiction. Most machines couldn’t walk unassisted. In 2024, the picture is different. Machines are improving at moving through space and navigating novel situations (such as those they might encounter on building sites).

During the 2011 Fukushima nuclear power plant meltdown, Japan lacked robots to send to the disaster site. Today, remote-controlled demolition and heat welding machines are standard, owing to exponential progress in the last decade.

Building sites can use robots to augment their operations in the following ways:

- Working alongside human workers to augment their capabilities

- Automate rote or repetitive building tasks that don’t require human expertise

- Perform hazardous tasks (and keep human operatives safe)

- Deal with the existing construction worker labour shortage in the UK and other advanced economies

Various companies are already investing in robots to assist construction workers with repetitive tasks. Take Construction Robotics, for example. It offers its Material Unit Lift Enhancer (MULE) system to address labour shortages and works by assisting workers move heavy concrete blocks into position on existing walls or groundwork plans. The company is also developing its Semi-Automated Mason (SAM) system, which prepares sections of brickwork by moving bricks into place, laying mortar, and fitting individual elements into position, increasing on-site productivity for over ten years. The firm estimates the tool can increase output by three to five times while lowering costs by over 50% and improving workplace health and safety.

Other companies are also developing robots for the construction industry. For example, Dusty Robotics is developing its FieldPrinter robot. The device enables operatives to print onto smooth concrete surfaces from building information modelling (BIM) to provide layout information for wiring, soffits, interior partitions, and more. FieldPrinter links directly to CAD files, performing line work automatically, offering a versatile end-to-end solution for more complex fit-outs.

Australian firm FBR also has a brick-laying robot named Hadrian X ready for prime time. The giant vehicle-mounted robot arm can lay single- and double-cavity walls for various construction types, including residential housing and commercial units, and is also suitable for steel and concrete lintels.

Hadrian X works by feeding blocks on a conveyor to the robot arm tip. The unit then picks up available bricks, placing them according to CAD instructions. The innovation lowers labour requirements and increases productivity significantly while letting workers avoid labouring at height.

Self-driving is also assisting on building sites. The technology is more practical in this setting than on public roads because crews can better control the surrounding environment. For example, Built Robotics already has an Automated Track Loader (ATL) for small-site excavations. The vehicle uses a combination of LiDAR, GPS, sensors, and base stations to find and measure material on excavation sites, ready to lift it from the ground. Teams can geofence the unit’s area of operations, getting it to dig for them while they attend to the rebar, concrete or drainage.

Royal Truck & Equipment is doing something similar, working with Micro Systems and Kratos Defence to build truck-mounted attenuators. These systems are used for road construction sites without barricades and keep workers safe. Applications include line painting, sign removal, bridge inspection and traffic light repairs.

Royal Truck & Equipment says trucks can follow workers, providing protection from traffic flowing from behind. Vehicles do not need drivers in some circumstances, reducing collision risks substantially. Removing workers from dangerous situations provides long-term safety and protection for firms.

Finally, some robot manufacturers are working on job site monitoring robots. These measure progress and update systems using real-time data.

Doxel AI is one such company with products in the works. Its product is a small-sized robot on caterpillar tracks that combines cameras and LiDAR to photograph and map the job site scene. Data feeds to central computers, showing managers how much work is being done.

Doxel AI is intelligent because it can classify how much material workers are using and deploying using onboard sensors and software. The machine has a similar eye as experienced managers and is expert at identifying progress (or lack thereof).

Ultimately, Doxel improves productivity by reducing the need to rework sections. Managers can see if projects or build elements are proceeding to plan in real-time, making adjustments on the fly if not.

Building Information Modeling

Building information modelling is also seeing advances because of artificial intelligence and other technologies. Solutions are becoming more professional and capable, reducing the risk of error and low productivity.

For example, Trimble (maker of Vico Office, Tekla Structures, and Sketch Up) offers 3D modelling tools with clash detection and integrated project management capabilities. These let teams see where conflicts are likely to occur during real-world construction efforts, and how to circumvent them.

Top BIM Company offers something similar. Product components include quantity takeoffs, 5D modelling, and clash detection. Construction firms can use insights to reduce resource usage and costs while improving coordination.

Work is also going into designing systems to detect whether operatives are following BIM plans. For example, Canadian firm Avvir makes a mobile scanner allowing operatives to find and detect deviations from BIM planning instantly (instead of waiting for errors to emerge). It emits lasers and detects distances to all surfaces within an environment before comparing them to the original sketches.

Avvir hopes the tools will prevent construction errors that cause delays and deviations from timetables. Reworking sections or changing plans is one of the costliest mistakes companies can make.

Finally, Dassault Systems is making its BIM more collaborative. The tool lets teams work together in the cloud. Anyone with access can modify a project in real time, allowing multiple users to work on a single integrated plan.

3D Printing

While bricklaying robots are one option for automating building projects, 3D printing is another. It offers the prospect of mass-producing homes and commercial units at low cost with almost zero labour input, raising productivity and efficiency, while improving safety.

Various companies are entering the sector and innovating, taking advantage of tremendous advances in 3D printing technology in recent years. For example, French company Constructions 3D has machines certified to “print” buildings, including the MiniPrinterEDU, the MiniPrinter Pro, and the MaxiPrinter – its largest tool. The device looks like a giant spider with a long printing head on the end of a robot arm. The company believes it offers the most cost-effective solution of all construction methods on the market, able to create complex cavity walls able to trap heat and protect eco-friendly insulation materials, like plant fibre.

Mighty Buildings is another firm in this space. It combines 3D printing with robotics and automation for the ultimate labour-saving experience. The primary aim is to use its equipment to create beautiful buildings with 99% less waste and time than conventional constructions. The firm believes it will complete the world’s first carbon-neutral homes by 2028, 22 years ahead of schedule

SQ4D is also thinking along the same lines. The company wants to make the construction industry faster and safer while enabling stronger low-cost buildings. To prove its technology, it recently completed the construction of a home in the U.S. for just $299,000, well below the average in its region in just 80 hours. The company believes it could build entire neighbourhoods in weeks with more machines and resources.

Finally, leading firm ICON is also making waves in the construction industry with its building-sized 3D printer. The machine combines robotics with a clever archway design to deliver intricate projects in hours.

The system includes the Vulcan printer and the Magma portable mixing unit. The former pipes fresh Lavacreate (ICON’s proprietary building material) to the latter, providing a constant stream of materials for optimal construction rate and precision.

Supporting these systems are the robots that wheel the printer into position. These can move the platform backwards and forwards, and raise it up and down as the build height increases. As print jobs continue, the robots adjust the height and position (similar to an ink printer), ensuring the printing head is above the target location. Due to its size, the machine doesn’t require repositioning for floor plans up to 3,000 square feet and constantly knows where it is, thanks to ICON’s BuildOS software suite.

ICON says the Vulcan can produce resilient, single-story homes faster than conventional methods. It can also do it with more waste while offering architects additional design freedom, allowing them to create buildings that align with their aesthetic preferences.

VR/AR

Despite the technologies' newness, virtual and augmented reality are already impacting the construction industry. Companies want to use these innovations to provide workers with additional information about building sites, improving productivity.

VR is being used for various purposes including:

- Enabling construction companies to improve their project planning and training by creating realistic simulations of building sites

- Enhancing site visualisations by providing AR overlays onto the real world, allowing workers to see multiple layers, reducing the risk of errors and reworking

- Improving the accuracy of tool usage

- Boosting collaboration between designers, architects and construction workers on the ground

Some companies are using VR to provide client tours without requiring them to go on-site. For example, San Francisco-based Holo Builder makes 360-degree visualisation software that management can use to determine site progress. Onboard VR facilities allow users to immerse themselves in the project from a distance.

Kalloc Studios has a similar idea with its Fuzor tool. The tool combines information from multiple software packages and fuses them into a single image for designers to see how their project will look in the real world. It is also compatible with VR, allowing them to get a sense of size, space, and proportions from within the finished room.

Meanwhile, Canvas wants to combine AR with BIM to compare work against modelling. The Florida-based outfit, founded in 2013, believes comparing models to reality daily can help managers ensure projects finish on time.

Construction Management Software

Finally, firms like Autodesk, Procore, and Buildertrend are innovating in the software space, and bringing new management tools to help construction work go off without a hitch.

For example, Fieldwise is an all-in-one job site management software that connects operatives in the field to the head office. It eliminates repetitive planning tasks and has been used on over one million projects.

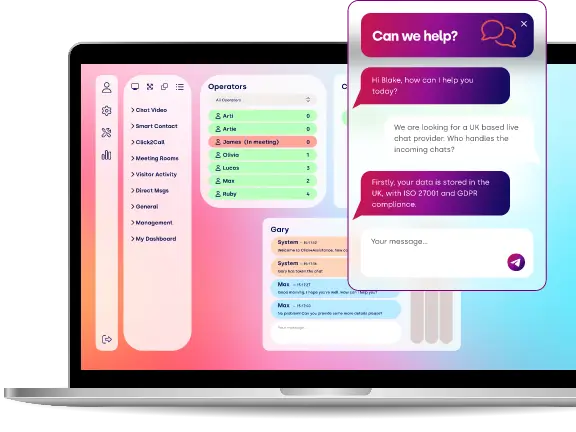

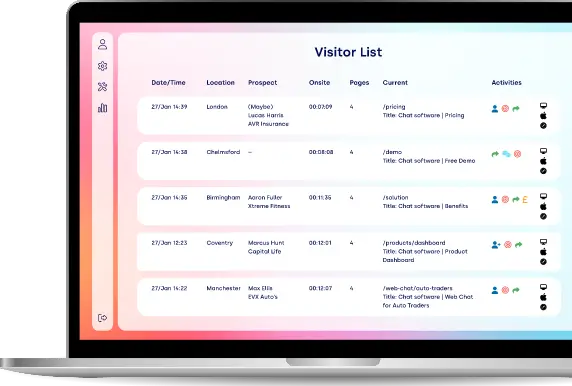

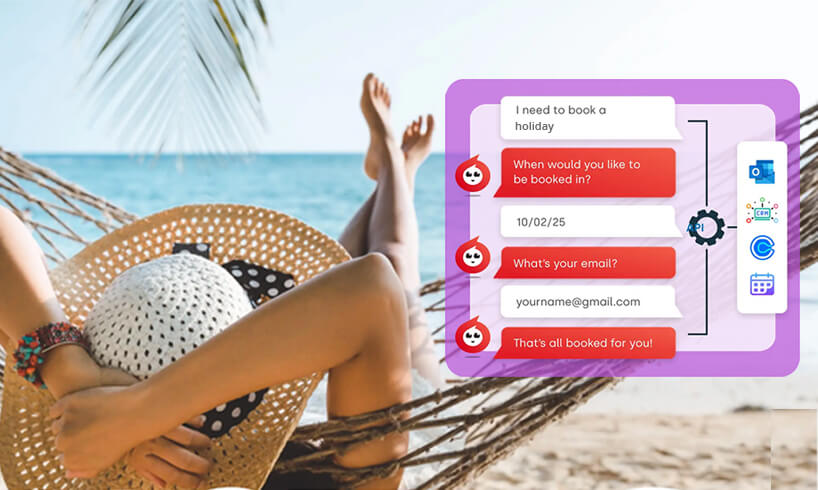

Procore is another option. It helps firms connect to every project contributor like our chatbot software, allowing disparate teams to work on projects and get the job done.

Finally, there’s the Autodesk construction cloud. It allows for better cost forecasting, data federation and forms completion tracking, ensuring it captures all critical information, with time saved on admin of up to 50%.

Wrapping Up

Ultimately, technology is revolutionising the building industry. Construction companies are becoming high-tech as the power of robotics, software, and AI bleed out into the real economy. Benefits include improved sustainability and safety, higher productivity, and faster constructions that more closely meet client specifications.